return to

return to  Bad pictures ? Click here

Bad pictures ? Click here

Tanks wheels in acrylic

Tanks wheels in acrylic

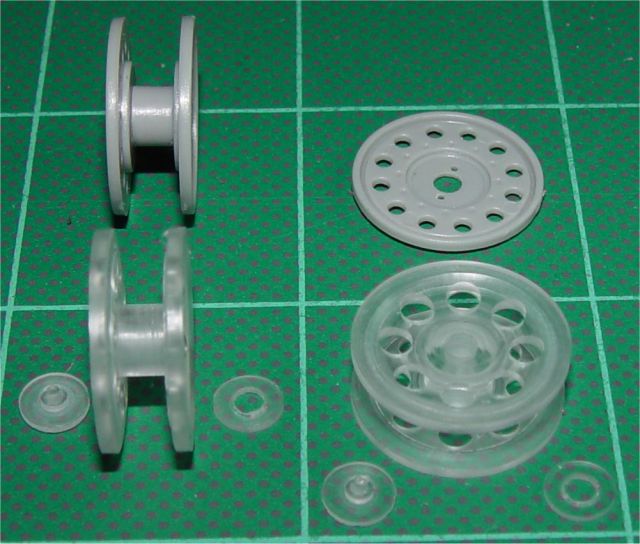

I was searching for an alternative to metal, preferably cheaper, that could be glued easier and was lighter in weight. I discovered near my house a place selling plastic, and in particular acrylic rods and plates. I wanted to try this material and see if it was easily workable and rigid enough, so I made a tank wheel, with many holes just to see if it would work.

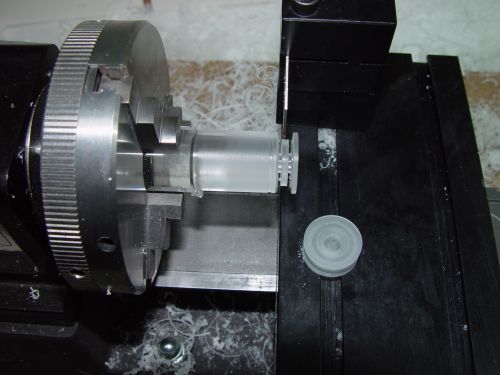

First step, separate the wheels from a piece of 3/4" rod. I choose to make the two sides of the wheel in one piece, digging in the material with the cutoff tool to create a large slit.

The acrylic can be cut at high rotation speed with a carbide bit, but where there is friction, as when using the cutoff tool, it melt ! So, in that case, I needed to use a very low rotation speed, and plenty of VARSOL (paint thinner) as lubricant.

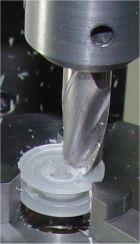

Than, I make a light plunge cut with a round end mill, using the fine Sherline rotary table.

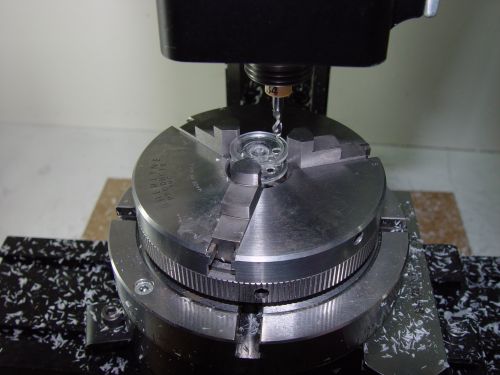

Last step, drill the holes, using an identical setup, with the rotary table you can easily set it up to drill any number of accurately drilled holes. The problem with acrylic is that it shatters easily, especially when thin. I broke several pieces by pushing too hard with the drill. Maybe I should have pre-drilled with a smaller size drill......

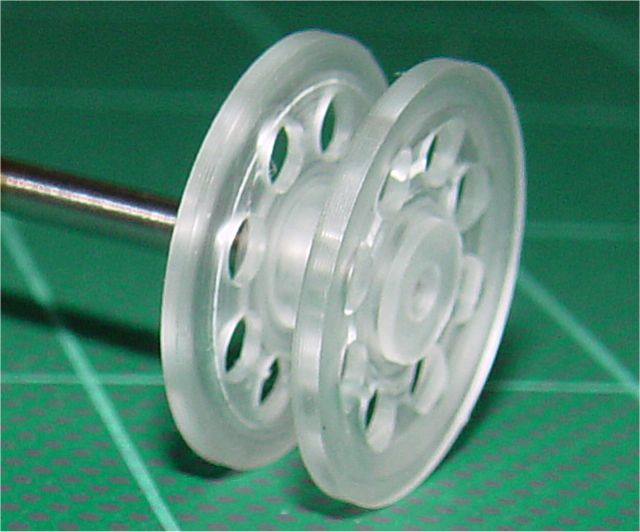

And here is the result. Above you can see a wheel from another tank model that I used as a template. You can also see the caps used to finalize the look, hiding the wheel axis. I used 1/4" rod for them.

A closer look.

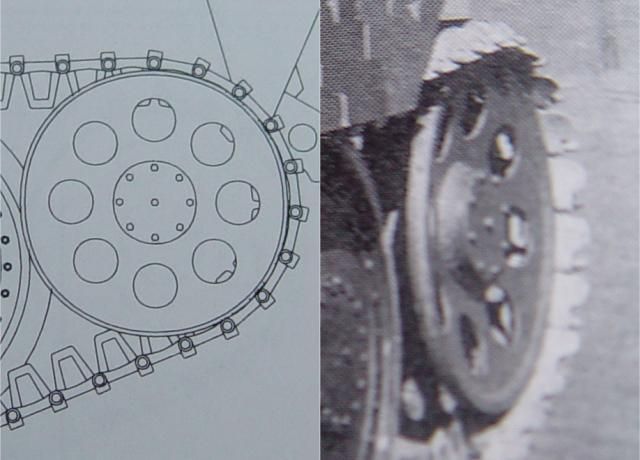

The plans I used, and a photograph of the real wheel.

Bad pictures ? Click here

Bad pictures ? Click here